Description

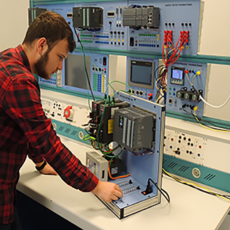

In this course, you will learn to use the Simatic S7 PLCs instruction set to process analog values and the PID control algorithm so you can achieve a closed-loop control system. A key element of the course is the use of equipment (ASTANK 2) providing an introduction to process engineering and closed-loop control. In this course, special attention is placed on the topics of complex hardware and software diagnostic functions, on the integrated PID controller technology functions and drive functions. There will be applications for measuring and controlling process parameters (flow, level, pressure) in open or closed loop, using classical control algorithms.

Target group: Electricians and engineers

Content:

• Processing of analog values

• Analog-numeric or numeric-analog conversion

• Standardization of analog input signals

• Upper and lower limits of analog values

• Differences between local variables and global variables

• 16/32-bit conversions

• Voltage/Current Input / Output Signals

• Analog sensors/analog actuators

• Open-loop control and closed-loop control, bipositional control

• PID control algorithm with flow and level control applications

Objectives:

At the end of this seminar, the trainees will be able to:

• Implement applications that involve the processing of analog values

• Integrate analog elements into a PLC program

• Use analog output values, connect analog input / output components correctly

• Implement bidirectional or PID bidirectional (level, flow, flow) control structures

• Adjust the parameters of the PID algorithm

• Run and test the control systems

Duration: 4 days

Note: Enrollment and participation in this course requires basic knowledge in the field